In high-speed food manufacturing, accuracy is everything — not just for quality control, but for cost, hygiene, and operational efficiency. Whether you're portioning sandwich fillings, pastes, or soft mixes, even a few grams of overfill can add up to thousands in wasted product each year.

That's where the Millitec VSD Volumetric Servo Depositor comes in.

What Is the VSD Servo Depositor?

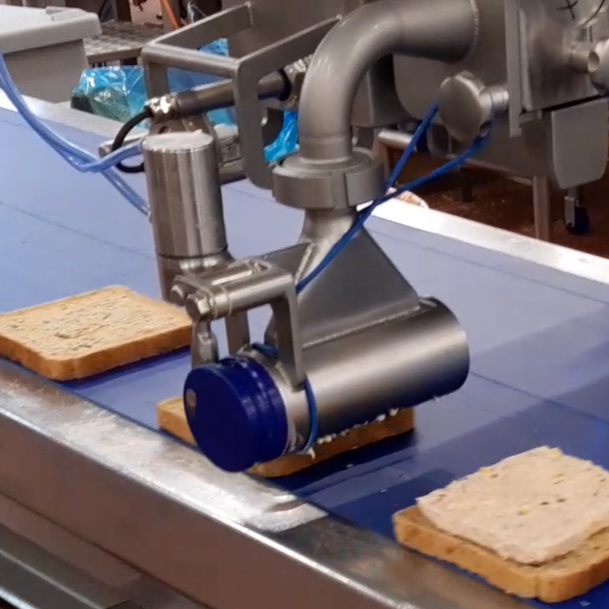

Part of Millitec’s automated sandwich line, the VSD is a servo-operated, volumetric depositor built for both direct depositing (up to 100 operations/minute) and sheeting (up to 60 operations/minute).

Unlike traditional pneumatic systems, the VSD gives you complete control over the deposit process — with touchscreen operation, full recipe handling, and programmable features like suck back, deposit delay, and density control.

That means less overfill, better portion control, and cleaner results.

Why Choose a Servo Depositor Over Pneumatic?

Older food depositor machines often rely on compressed air, which can compromise hygiene, increase energy use, and limit precision. In contrast, the VSD:

- Reduces the risk of contamination by eliminating dirty air from the system

- Offers programmable precision down to 0.1g

- Saves up to £4,000 per year in energy costs compared to pneumatic alternatives

9 Key Benefits of the VSD

- Highly Accurate: Adjust to 0.1g for repeatable, consistent results.

- Energy Efficient: Save up to £4,000 per year compared to traditional pneumatic systems.

- Hygienic Construction: Eliminates the need for dirty compressed air, reducing contamination risk.

- Fast Changeovers: Minimal change parts and rapid reloads mean less downtime.

- Touchscreen & Recipe Handling: Set up, repeat, and switch between products with ease.

- Handles Particulates: Can manage pieces up to 50mm with a built-in force feeder.

- Self-Levelling & Suck Back: Prevents dripping and ensures smooth delivery.

- Hygienic Design: Designed for easy strip-down and cleaning process.

- Fully Mobile and Line-Ready: Works seamlessly with other Millitec equipment, including conveyors, butterers, and cutters.

Ideal Applications in Sandwich Production

From sheeting butter or mayonnaise to depositing chunky fillings with particulates, this machine helps manufacturers maintain consistent portion control with minimal waste. But its flexibility goes further. It’s equally suited to:

- Wraps

- Sandwiches

- Sub rolls

- Other hygienic food production lines requiring high-speed depositing

Get More Accuracy with Less Waste

Want to reduce waste, improve hygiene, and streamline your production line? Download the VSD brochure, or get in touch with our team to see how it could work in your setup.

Comments are closed for this post.